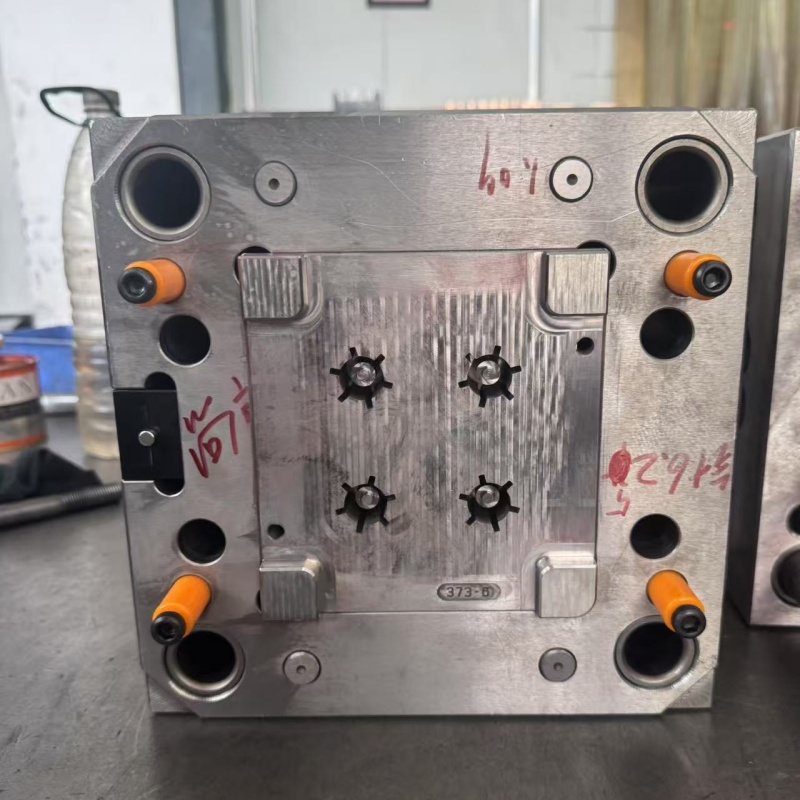

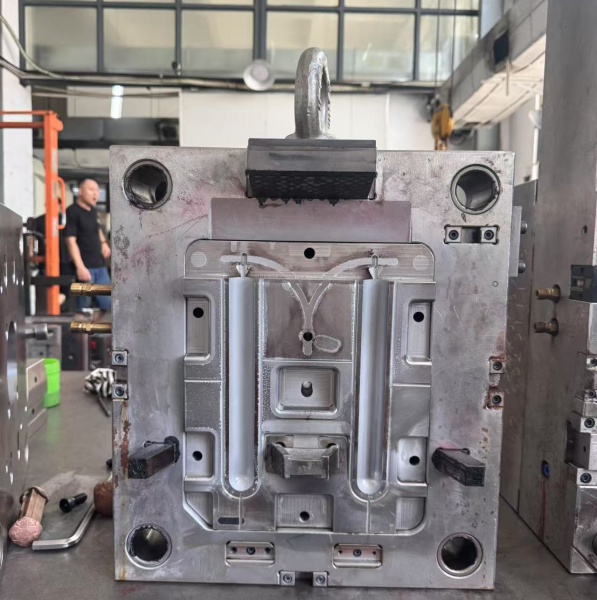

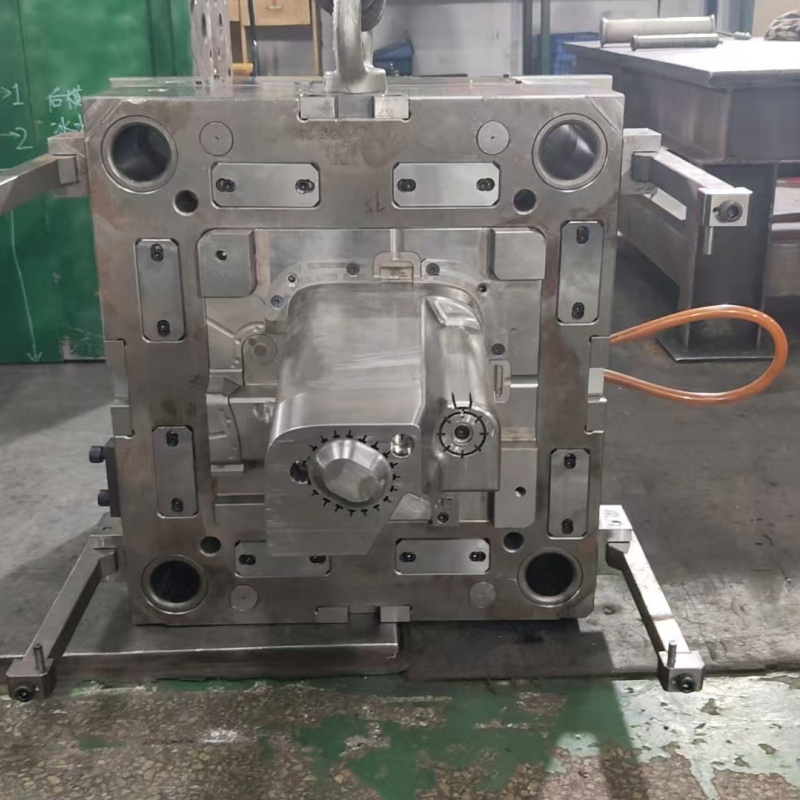

Plastic Wall Shower Panel Mould USe On Bathroom Items

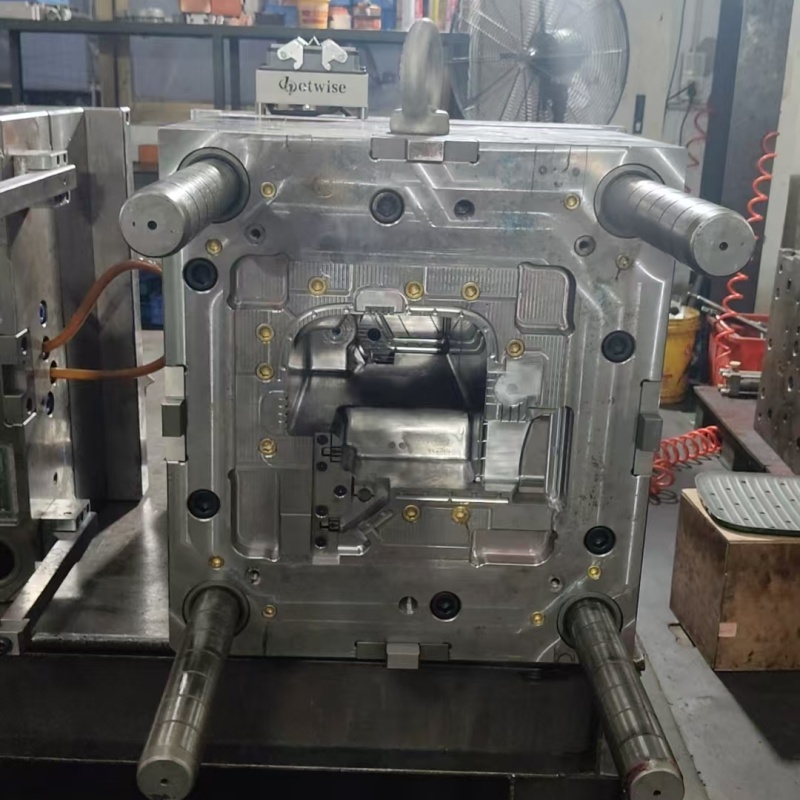

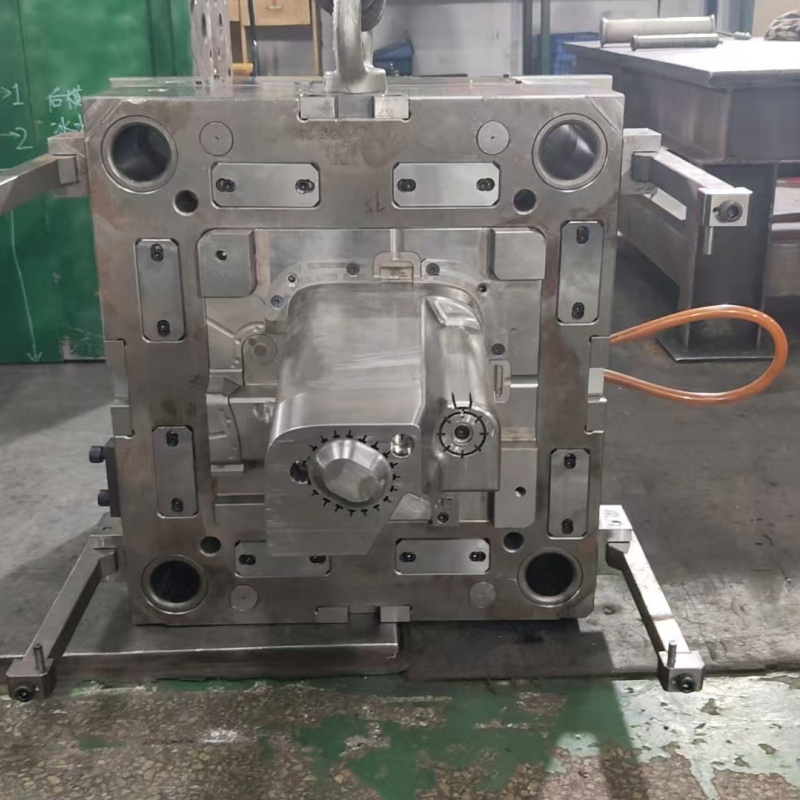

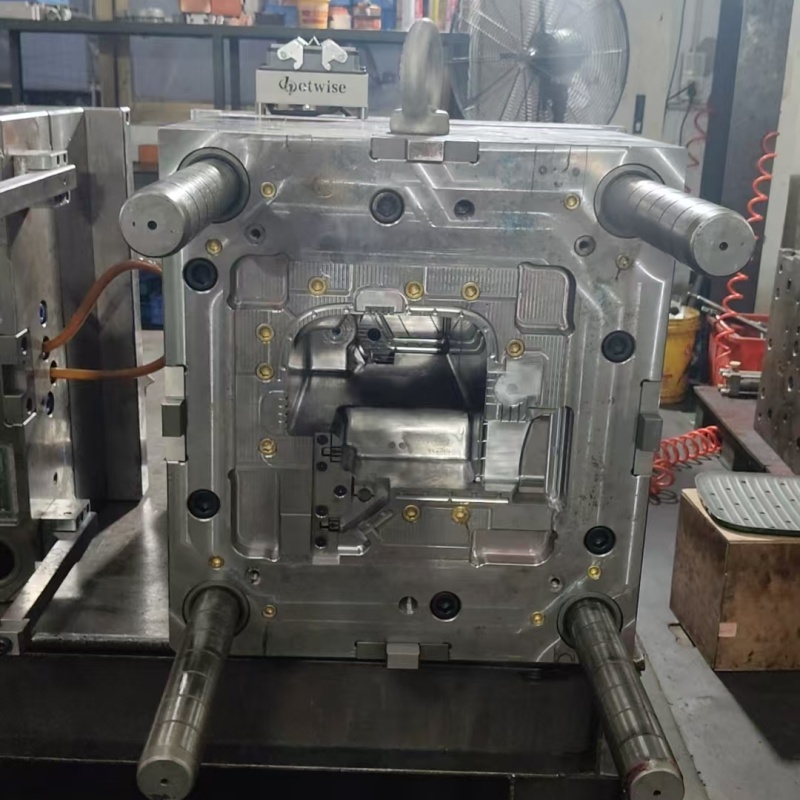

Manufacturing Technique:injection

Mould Core:S136

Mould Base :45# steel

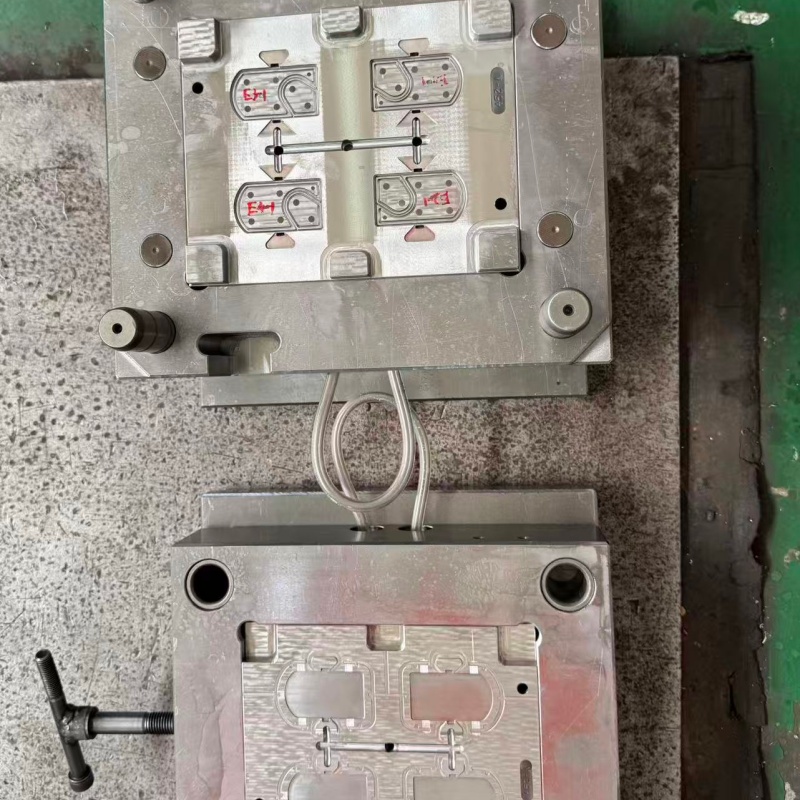

Cavity:4

Delivery Time:45days for mold trail test

Product Specification:

Stainless Steel Medical Injection Molding Companies |

factory | mould name | mold cavity | mold core | mold base | mold delivery time | shot(times) | circle time(second) |

fengjin | plastic mold | 4 | S136 | 45# | 45days | 400000 | 40 |

Of course. Here is a professional introduction to the mold for a plastic wall shower panel product, written in English.

---

### **Introduction to the Injection Mold for Plastic Wall Shower Panels**

The production of high-quality, aesthetically pleasing, and durable plastic wall shower panels is fundamentally dependent on the precision and sophistication of the injection mold used in their manufacturing. This mold is not merely a tool but a complex engineering system designed to transform raw plastic materials into finished products with consistent excellence. Below is an overview of the key aspects of a modern shower panel injection mold.

#### **1. Core Design and Construction**

* **High-Grade Mold Steel:** The mold is typically constructed from premium, hardened steels (such as P20, H13, or S136 stainless steel) to withstand the high injection pressures, abrasive filled materials (like minerals for weight), and constant thermal cycling. This ensures a long production life and maintains dimensional stability over hundreds of thousands of cycles.

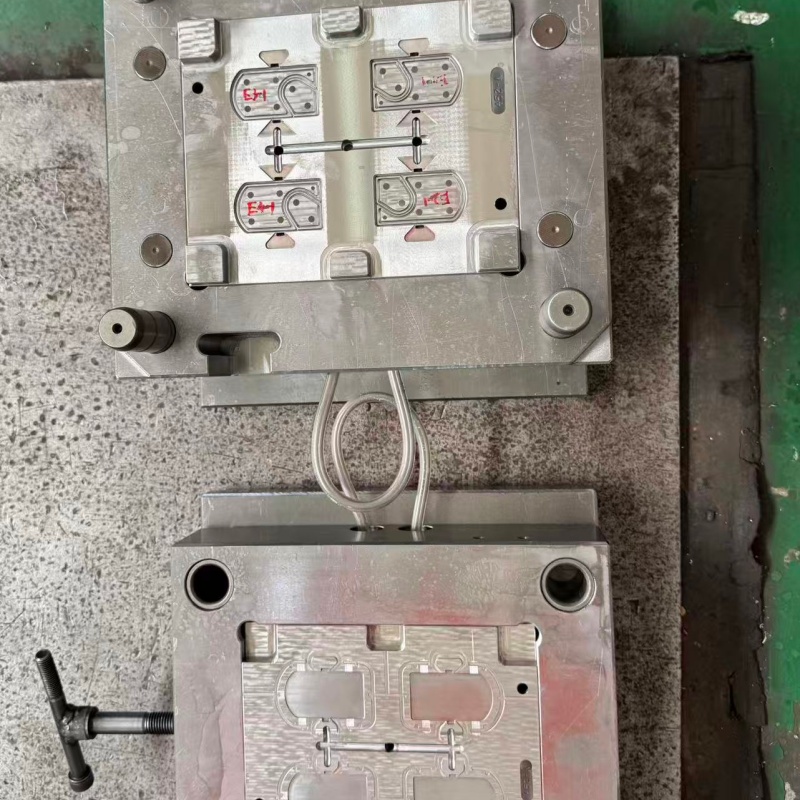

* **Multi-Cavity Design:** To optimize production efficiency and output, molds are often designed with multiple cavities. This allows for the simultaneous injection of several shower panels or their key components in a single machine cycle, significantly reducing the per-unit cost and time.

* **Complex Core and Cavity:** The core and cavity are the heart of the mold, directly forming the shower panel's shape. They are CNC-machined to extreme precision to capture every design detail:

* **Tile Patterns:** Realistic stone or tile textures.

* **Recessed Shelves:** For soap and shampoo.

* **Body Jets & Massage Nozzle Openings:** Precisely located holes for plumbing fittings.

* **Backside Reinforcement Ribs:** Critical for providing structural rigidity and preventing deflection under water pressure and temperature changes.

#### **2. Advanced Gating and Runner System**

* **Hot Runner System:** Modern shower panel molds almost exclusively use hot runner systems. This system keeps the plastic molten inside the mold's channels, eliminating solid cold runners. The benefits are substantial:

* **Reduced Waste:** No runner scrap to regrind and reprocess.

* **Improved Aesthetics:** Allows for more flexible gate placement in non-critical areas, minimizing visible marks on the finished panel.

* **Faster Cycle Times:** As the material in the runners remains hot, the injection process is more efficient.

#### **3. Sophisticated Cooling System**

A shower panel is a large part with a significant surface area. Achieving a uniform and efficient cooling process is paramount.

* **Conformal Cooling Channels:** These channels are designed to follow the exact contours of the mold's surface. This ensures even heat extraction from the entire part, preventing warpage, sink marks, and internal stresses. It also drastically reduces the cycle time, as the part solidifies faster and more uniformly.

#### **4. Ejection and Venting**

* **Integrated Ejection System:** A network of ejector pins, sleeves, and sometimes stripper plates is meticulously placed to apply even force across the large part surface for a smooth, damage-free release from the mold after cooling.

* **Strategic Venting:** Proper venting is crucial to allow trapped air and gases to escape during the high-speed injection phase. Inadequate venting can cause defects like burns, short shots, or poor surface finish. Vents are strategically placed along parting lines and within ejector pins.

#### **5. Surface Finishing Technologies**

The visual appeal of a shower panel is a primary selling point. The mold's surface finish directly translates to the product's finish.

* **Texturing (ETX):** Electrical Discharge Texturing (EDT) or laser etching is used to create realistic surface patterns like matte, gloss, linen, or natural stone on the mold steel. This texture is then perfectly imparted onto every shower panel produced.

* **Polishing:** For high-gloss panel surfaces, the mold cavity is polished to a mirror finish.

.

Other plastic injection mould products we make for customer,we can also make mold for sanitary ware,sports parts ,electric appliance and so on.

Our Injection Factory Shop,we have 15 set injection machine in different size,big and small ,max is 1228ton,can make pastic parts max 1.5*1.2m

Stainless Steel Medical Injection Molding Companies

We can offer google mould,neck massage equipment mould,kit mould and so on.Welcome to contact us for mould customized.

Normally we'll have 35-45 days for plastic mold production.Step as below :customer offer samples-our designer finish the 3D and send for customer confirmation-start to design the mold -order the steel - CNC processing-electrosparking-assemble the mould-test the injection mould-send plastic parts sample to clients-packing-delivery-customer feedback -new order

Packing by wood crate as standard export packing

For other plastic products customized please send us 3d drawing or samples for quotation,we'll offer you suggestions on mold and design.And offer best price to start.These years,we have booth on bangladesh,russia,turkey,and morocoo for plastic and rubber fair .welcome to contact us for more that if we can have a chance to meet and talk more details on items custom at fair or visit our factory on purposeful.